Introduction

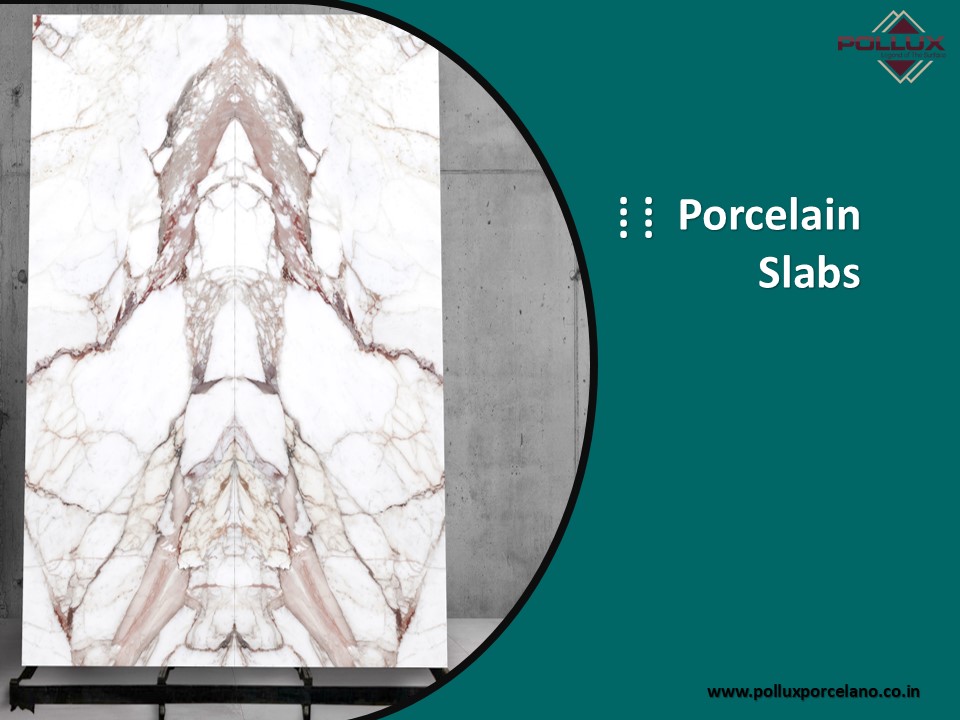

Porcelain slabs are a modern innovation revolutionizing interior design and architectural projects. Think of them as oversized tiles, typically measuring up to 10 feet long and 5 feet wide, but with a thickness ranging from 6 to 12 millimeters. These slabs are made from compressed porcelain clay that’s fired at extremely high temperatures, resulting in a material that’s durable, versatile, and incredibly resilient.

The rising popularity of porcelain slabs in contemporary design circles can be attributed to several key factors. Firstly, their large size offers seamless surfaces with minimal grout lines, creating a sleek and uninterrupted aesthetic. This makes them ideal for creating expansive countertops, flooring, wall cladding, and even furniture pieces.

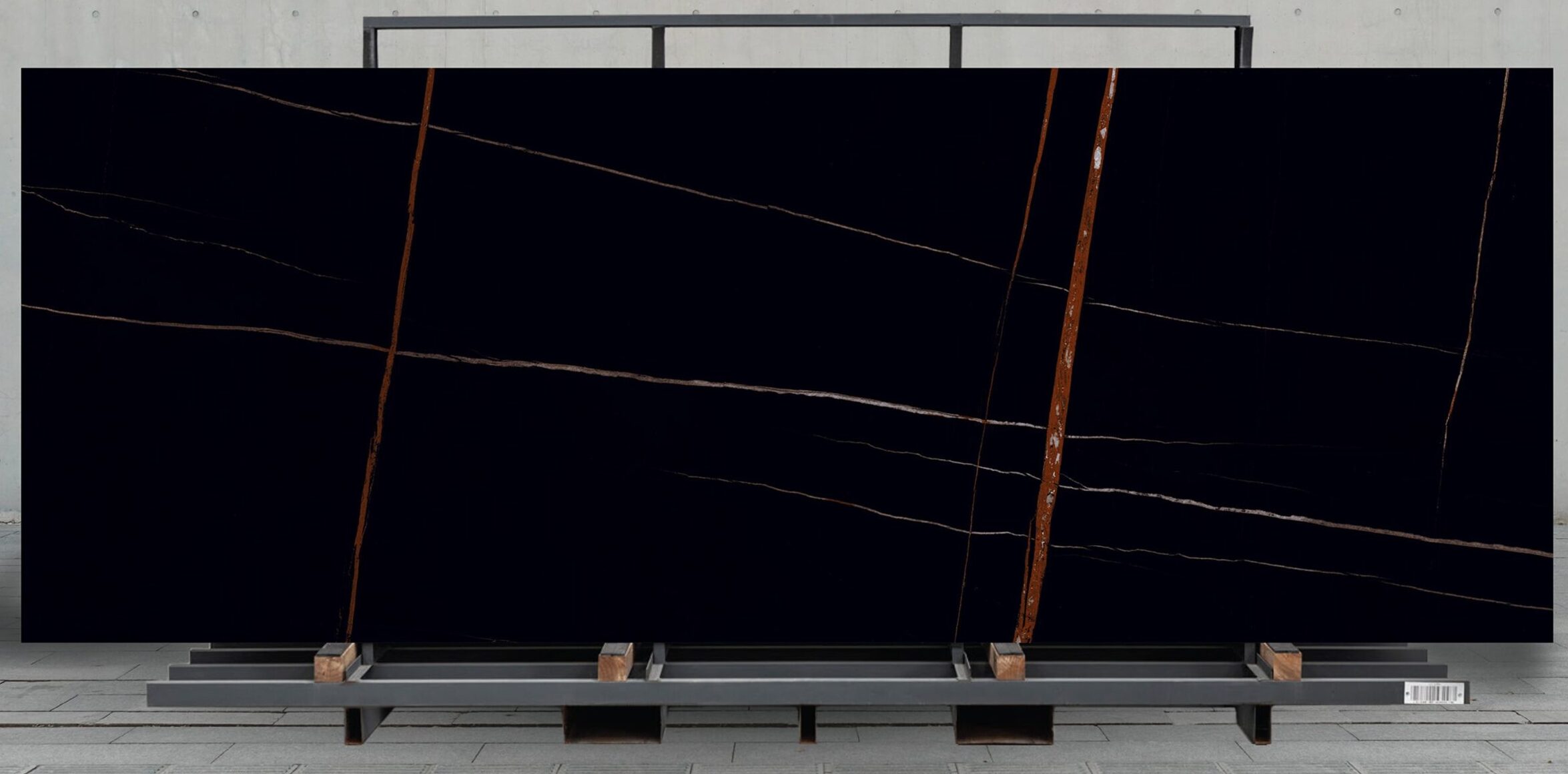

Additionally, porcelain slabs boast a wide range of design possibilities. They can mimic the look of natural materials like marble, granite, wood, and concrete, but with none of the maintenance drawbacks. Unlike natural stone, porcelain is non-porous, stain-resistant, and requires minimal upkeep, making it a practical choice for both residential and commercial spaces.

Furthermore, the versatility of porcelain slabs extends beyond aesthetics. They are lightweight compared to traditional stone slabs, making them easier to transport, handle, and install. This not only reduces installation time and costs but also opens up design possibilities for applications such as vertical surfaces and outdoor installations.

What are Porcelain Slabs?

Porcelain slabs, also known as porcelain tiles or porcelain panels, are large-format ceramic tiles typically used for countertops, walls, floors, and other surfaces. They have gained popularity in recent years due to their remarkable durability, versatility, and aesthetic appeal. Here’s a breakdown of their composition, manufacturing process, and unique properties:

Composition: Porcelain slabs are made from a mixture of fine-grain clay, minerals, and other natural materials. This composition is highly refined and processed to create a dense, non-porous surface. The addition of various pigments and textures during manufacturing allows for a wide range of colors and finishes, including designs that mimic the look of natural stone like marble and granite.

Manufacturing Process: The manufacturing process of porcelain slabs involves several steps:

- Mixing: Raw materials including clay, feldspar, silica, and other minerals are mixed together with water to form a slurry.

- Pressing or Extrusion: The slurry is pressed or extruded into large sheets or slabs using hydraulic presses or extrusion machines.

- Drying: The formed slabs are dried to remove excess moisture, typically in a controlled environment to prevent warping or cracking.

- Firing: The dried slabs are fired in kilns at extremely high temperatures, typically exceeding 1200°C (2200°F). This process, known as vitrification, transforms the materials into a dense, durable, and non-porous structure.

- Finishing: After firing, the slabs may undergo additional processes such as glazing, polishing, or texturing to achieve the desired surface finish.

Unique Properties: Porcelain slabs offer several unique properties that distinguish them from traditional materials like marble and granite:

- Durability: Porcelain slabs are exceptionally durable and resistant to scratches, stains, heat, and moisture. Their non-porous surface makes them easy to clean and maintain, suitable for high-traffic areas and outdoor use.

- Versatility: Porcelain slabs come in a variety of sizes, thicknesses, colors, and textures, allowing for endless design possibilities. They can be used for countertops, backsplashes, wall cladding, flooring, and even furniture.

- Aesthetic Appeal: Porcelain slabs can mimic the look of natural stone, including marble, granite, limestone, and travertine, with remarkable realism. They offer consistent color and veining patterns, eliminating the variability found in natural stone.

- Large Format: Porcelain slabs are available in large formats, with sizes exceeding traditional tile dimensions. This means fewer grout lines, creating a seamless and contemporary look.

- Environmentally Friendly: Porcelain production often utilizes recycled materials, and the durability of porcelain slabs reduces the need for frequent replacements, making them an environmentally friendly choice.

Comparison with Marble and Granite: When compared to traditional materials like marble and granite, porcelain slabs offer several advantages:

- Durability: Porcelain slabs are more durable and less prone to scratching, staining, and etching compared to marble and some types of granite.

- Maintenance: Porcelain slabs require minimal maintenance and are easier to clean than marble and granite, which may require periodic sealing.

- Consistency: Porcelain slabs offer consistent color and pattern throughout, whereas natural stone like marble and granite can vary significantly in appearance from slab to slab.

- Cost: While the initial cost of porcelain slabs may be higher than some types of granite, they often provide better long-term value due to their durability and low maintenance requirements.

Applications in Interior Design

Kitchen Countertops: Porcelain slabs are an excellent choice for kitchen countertops due to their resistance to heat, scratches, and stains. They offer a sleek and modern look to the kitchen space. You can find porcelain slabs in various colors and patterns to suit different kitchen styles.

Example: A kitchen with a large, seamless porcelain slab countertop in a marble-like pattern can create a luxurious and elegant ambiance.

Backsplashes: Porcelain slabs make for stunning backsplashes in kitchens and bathrooms. They provide a seamless and easy-to-clean surface while adding visual interest to the space. Porcelain slabs can mimic the look of natural stone, concrete, or even intricate patterns.

Example: A kitchen backsplash featuring porcelain slabs in a bold geometric pattern adds a contemporary touch to the space.

Flooring: Porcelain slabs are an ideal choice for flooring in high-traffic areas due to their durability and low maintenance. They can mimic the look of hardwood, natural stone, or concrete while offering superior resistance to scratches and moisture.

Example: A living room with large-format porcelain slab flooring in a wood-look finish creates a warm and inviting atmosphere with the practicality of porcelain.

Wall Cladding: Porcelain slabs can be used to clad entire walls or create accent walls in various rooms, including living rooms, bedrooms, and bathrooms. They add texture, depth, and visual interest to the space while providing a durable and easy-to-clean surface.

Example: A bathroom featuring floor-to-ceiling porcelain slab wall cladding in a marble-inspired design exudes luxury and sophistication.

Furniture: Porcelain slabs can be used to create unique and stylish furniture pieces such as tabletops, side tables, and shelving. They offer a sleek and contemporary look while being resistant to scratches, stains, and heat.

Example: A dining table with a porcelain slab tabletop in a minimalist design adds a touch of elegance to the dining area while being practical and easy to maintain.

Design Inspirations:

Marble-Inspired Elegance: Use porcelain slabs with marble-like patterns for countertops, backsplashes, and wall cladding to create a luxurious and timeless look.

Industrial Chic: Opt for concrete-look porcelain slabs for flooring and wall cladding to achieve an industrial-inspired aesthetic with a modern twist.

Wood-Look Warmth: Choose porcelain slabs with wood-look finishes for flooring and furniture to bring warmth and texture to contemporary spaces without sacrificing durability.

Geometric Patterns: Experiment with porcelain slabs featuring bold geometric patterns for backsplashes and accent walls to add visual interest and personality to the room.

Advantages Over Traditional Materials

Non-Porous Nature: Porcelain slabs are manufactured using advanced technology that results in a dense, non-porous surface. This characteristic makes them highly resistant to water absorption, preventing the growth of mold, mildew, and bacteria. As a result, they are ideal for use in areas prone to moisture exposure, such as kitchens, bathrooms, and outdoor spaces.

Resistance to Stains: The non-porous surface of porcelain slabs makes them inherently resistant to stains from common household items such as wine, coffee, and oil. Unlike natural stone, which may require regular sealing to maintain its stain resistance, porcelain slabs offer long-term protection against unsightly stains, ensuring easy cleanup and maintenance.

Scratch Resistance: Porcelain slabs are exceptionally durable and resistant to scratches and abrasions, making them suitable for high-traffic areas such as floors, countertops, and tabletops. This resilience to surface damage ensures that porcelain surfaces retain their pristine appearance even after years of use, reducing the need for costly repairs or replacements.

Heat Resistance: Porcelain slabs exhibit excellent heat resistance, allowing them to withstand high temperatures without warping, cracking, or discoloration. This property makes them ideal for use in areas exposed to heat sources such as stovetops, ovens, and outdoor grills, providing peace of mind and longevity to the installation.

Low Maintenance Requirements: Unlike natural stone, which often requires specialized cleaning products and regular maintenance to preserve its appearance, porcelain slabs are relatively low maintenance. Routine cleaning with mild soap and water is typically sufficient to keep porcelain surfaces looking fresh and vibrant, saving time and effort over the long term.

Aesthetic Appeal of Natural Stone: Despite their practical advantages, porcelain slabs also offer the aesthetic appeal of luxurious natural stone. Advanced manufacturing techniques allow for the replication of the intricate veining, textures, and color variations found in natural stone, providing homeowners and designers with a wide range of options to achieve the desired look and feel of natural stone without the associated maintenance challenges.

Versatility in Design: Porcelain slabs come in a variety of sizes, thicknesses, and finishes, offering unparalleled versatility in design applications. Whether used as flooring, wall cladding, countertops, or outdoor paving, porcelain slabs can be customized to suit any aesthetic preference or functional requirement, allowing for seamless integration into diverse architectural styles and interior design schemes.

Innovations and Trends

Larger Slab Sizes: Manufacturers are pushing the boundaries of size, offering increasingly larger porcelain slabs. These larger formats, sometimes exceeding traditional dimensions like 10 feet by 5 feet, allow for seamless installations and reduced grout lines, creating a sleek and modern look in both residential and commercial spaces.

Ultra-Thin Profiles: Ultra-thin porcelain slabs, often measuring just a few millimeters thick, are gaining popularity for their versatility and lightweight properties. These thin slabs are easier to handle and transport, making them ideal for applications such as wall cladding, furniture, and even exterior facades.

Advanced Printing Technologies: Innovations in printing technologies have enabled manufacturers to create porcelain slabs with incredibly realistic patterns and textures. High-definition inkjet printing techniques can mimic the look of natural stone, wood, concrete, and other materials with remarkable accuracy, offering a wide range of design options for architects, designers, and homeowners.

Integration of Smart Features: With the rise of smart homes and the Internet of Things (IoT), some porcelain slab manufacturers are incorporating smart features into their products. This can include embedded sensors for temperature monitoring, LED lighting systems, or even wireless charging capabilities. These integrated technologies add functionality and convenience to porcelain surfaces, enhancing their appeal in modern living spaces.

Sustainability: There’s a growing emphasis on sustainability in the production of porcelain slabs. Manufacturers are implementing eco-friendly practices, such as using recycled materials in production, optimizing energy efficiency, and reducing water consumption. Additionally, some companies offer porcelain slabs that are recyclable at the end of their lifecycle, further reducing environmental impact.

Customization and Personalization: Advances in manufacturing techniques have made it easier to customize porcelain slabs to meet the specific needs and preferences of customers. This includes bespoke colors, patterns, and textures, as well as the ability to create unique designs through digital printing and surface treatments. Customized porcelain slabs allow for greater creative freedom in interior and exterior design projects.

Tips for Selection and Maintenance

Color:

- Consider the overall aesthetic of your space. Do you want a bold statement or a more subtle backdrop?

- Think about how the color will complement other elements in the room, such as cabinets, countertops, and flooring.

- Keep in mind that lighter colors can make a space feel more open and airy, while darker colors can add depth and drama.

Finish:

- Matte finish: Offers a more natural, understated look and is less prone to showing fingerprints and water spots.

- Polished finish: Provides a sleek, glossy appearance that reflects light and can make a space feel more luxurious.

- Textured finish: Adds depth and dimension to the surface, making it ideal for outdoor applications or areas where slip resistance is important.

Thickness:

- Consider the structural requirements of your project. Thicker slabs are generally more durable and suitable for high-traffic areas or heavy-duty applications like kitchen countertops.

- Thinner slabs are lighter and easier to handle, making them a good choice for wall cladding, furniture, or other vertical installations.

Maintenance guidelines for porcelain slab installations:

Regular Cleaning:

- Use a soft, damp cloth or mop with mild detergent to clean the surface regularly.

- Avoid abrasive cleaners or scouring pads that can scratch the surface.

- For textured finishes, use a soft brush to remove dirt and debris from the crevices.

Stain Prevention:

- Wipe up spills promptly to prevent staining, especially on lighter-colored slabs.

- Use coasters or trivets under hot pots and pans to protect the surface from heat damage.

- Consider applying a penetrating sealer to help repel stains and make cleaning easier, especially for high-traffic areas like kitchen countertops.

Avoid Impact Damage:

- Handle porcelain slabs with care to avoid chipping or cracking during installation.

- Use protective pads or mats under heavy objects to prevent scratches or impact damage.

Outdoor Maintenance:

- For outdoor installations, regularly sweep or hose down the surface to remove dirt, leaves, and other debris.

- Consider applying a UV-resistant sealant to protect the surface from fading or discoloration due to sun exposure.